High density polyethylene (HDPE)

What is HDPE?

High density polyethylene sheets are referred to as HDPE. A thermoplastic manufactured from petroleum is called HDPE. With commercial uses in mind, Monopoly International offers HDPE, and our finest plastic cutting sheets are designed for exceptional flatness and uniformity.

HDPE cutting board sheets are ideal for commercial cutting board demands and secure for direct food applications since they are NSF rated and FDA approved. In addition to the typical 24×24 plastic cutting board, we also manufacture custom-sized high density polyethylene (HDPE) cutting boards.

White plastic cutting boards and cutting sheets are often seen in front of the house prep areas or buffet lines, whereas black industrial cutting boards are typically found in restaurant back rooms. HDPE is available in a broad range of shapes and sizes.

More information about other Monopoly-int products in Turkey : low-density polyethylene (LDPE)

You can expect that High density polyethylene cutting sheets tailored to the area’s and the company’s demands are used to produce the majority of industrial cutting surfaces. In order to meet any desired commercial or industrial cutting board use, HDPE may be cut to any desired size and the edges can be rounded. The edges are exceedingly smooth and splinter-free when rounded. For indoor uses, HDPE is ideal.

This versatile material has high chemical resistance and a reasonable price to fit a broad range of applications. There are many different sizes, colors, thicknesses, and customization possibilities available for our variety of High density polyethylene sheets. Monopoly International is one of the most reliable HDPE suppliers.

Because polyethylene sheets are impact, moisture, and chemical resistant, they are perfect for machined components, cutting boards for industry, wear strips, tank linings, animal confinement, material handling systems, and other uses. Due to its resistance to splintering, decay, and the retention of hazardous microorganisms, HDPE is preferred by businesses, schools, and other organizations. To begin, just choose the appropriate thickness, width, length, and quantity.

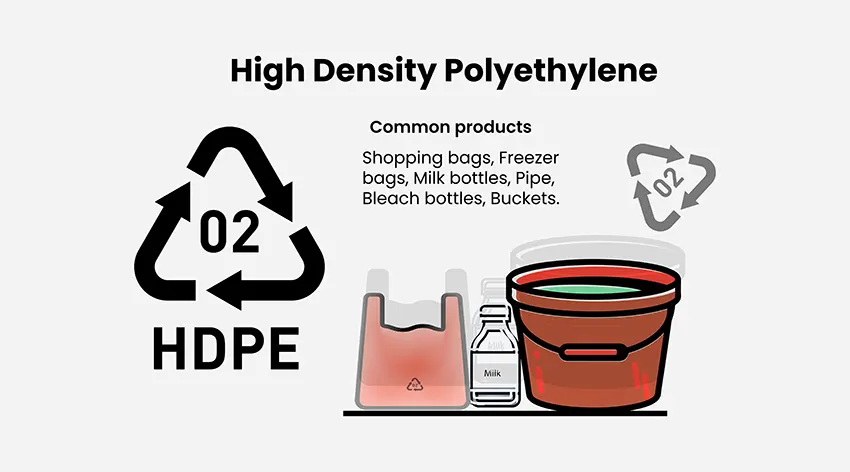

Common products that are HDPE

HDPE suppliers | What Advantages Does HDPE Plastic Offer ?

High Density Polyethylene (HDPE) sheets that are industrial-grade, food-grade, and authorized by the FDA, NSF, and USDA are designed to be durable, safe, and minimal maintenance. They provide a gripping surface with roughness that makes holding food secure. You can buy HDPE from Monopoly International, one of the best HPDE manufacturers in the world.

More information about other Monopoly-int services in Turkey : Recycled PET suppliers

These additional advantages are all included:

- Moldable and easily melted

The inherent malleability of this polymeric substance is one of its main advantages. In light of this, HDPE in particular shines. HDPE has a high melting point, which keeps it stiff even at very high temperatures. The plastic material may be swiftly and effectively molded for use in a range of uncommon applications, such as cutting boards, detergent bottles, milk jugs, food storage containers, corrosion-resistant pipes, geomembranes, plastic lumber, and so much more, after it has achieved its melting point.

- Corrosion Protection

Due to its resistance to decay, mildew, and mold, HDPE is the best material for water delivery subterranean pipe. HDPE is a great material for food and beverage containers since it is long-lasting and weather-resistant and can be sanitized by boiling. Additionally, HDPE has exceptional resistance to naturally occurring chemicals present in soil and can tolerate the majority of strong mineral acids and bases. In addition, the substance is almost impenetrable to water, solvents, acids, detergents, and cleaning agents.

- Strong to Density Ratio

HDPE has a density that may vary; however it is just slightly higher than LDPE (low-density polyethylene). The linear structure of HDPE, however, means that it has no branching when seen under a microscope, giving it more tensile strength and intermolecular forces than LDPE. Because of this, a 60-gram HDPE container can securely transport more than one gallon of liquid or around eight pounds of weight.

- Simple to Recycle

Given how much plastic we consume on a daily basis, plastic recycling should be one of the most significant considerations when choosing a material. HDPE plastic, fortunately, is readily recycled, preventing non-biodegradable trash from ending up in landfills and assisting in the up to 50% reduction in plastic production! HDPE can be the right plastic for you if you’re seeking for a reasonably priced, ecologically friendly substance.

request a quote

Why Use High density polyethylene (HDPE) ?

In order to achieve sustainable and cheap production and project objectives, HDPE often substitutes heavier materials. because of its excellent malleability, stiff strength, and resistance to corrosion. The ideal material for strength, cost-effectiveness, and environmental friendliness is HDPE.

Apparently, one survey says “Wood is more difficult to clean than nonporous surfaces like plastic or glass, making them better for food safety. Due to its inherent porousness, wooden cutting boards’ minuscule cracks and grooves may operate as a breeding ground for germs. For this reason, wooden cutting boards are prohibited in commercial kitchens.”

More information about other Monopoly-int services in Turkey : Recycled polypropylene (PP) Suppliers

If you need a LDPE supplier, you can contact our experts Quotation submission form Contact us

What distinguishes smooth from textured high density polyethylene plastic (HDPE) sheets?

HDPE is perfect for such a broad variety of applications since it is not changed by chemicals, moisture, or impact. Smooth HDPE plastic may be used for industrial purposes like livestock confinement or chemical tank linings as well as educational uses like binders, displays, and machined components. The phrase “plastic cutting board” most often refers to textured HDPE plastic, which may be customized in size and breadth depending on the user and the intended use.

Custom plastic cutting boards of various sizes and forms are available from Monopoly International suppliers. The texture is crucial because it prevents the HDPE from slipping and makes it a perfect cutting surface.

The boards have a texture on both sides, allowing for dual usage, and the roughness also keeps the user’s knife from becoming dull over time.

Although our commercial plastic cutting boards’ smooth HDPE surface is technically food safe, it would not be as useful for chopping or prepping food as our textured HDPE does since it is not porous.

Are HDPE and Polypropylene (PP) the same thing?

No. A thermoplastic polymer, often known as polypropylene (PP) or polypropene, is a versatile plastic material that hardens or becomes solid as it cools. Even after being repeatedly chilled and heated, it maintains its integrity. It melts into a liquid when heated to its melting point. Propylene serves as the monomer that makes up polypropylene.

PP is a substance that is often used in packaging, textiles, automobile components, and other products. What sets PP distinct from High Density Polyethylene The density, temperature, and UV resistance of polyethylene vary. Since PP has a lower density than HDPE, it works well for molded objects that are lighter in weight.

Its melting point is between 266 and 340 degrees Fahrenheit. Both PP and HDPE provide strong chemical and UV resistance; however, as PP needs additional stabilization, HDPE may be preferable in many situations where UV resistance is a key feature.

Four typical uses for HDPE

- Plastic bottles: Water bottles serve probably the most common casual introduction for most individuals to strong plastic. Due to the fact that it won’t leach into the contents of the bottles, HDPE is excellent for blow-molding applications, especially food and beverage containers. HDPE is also recyclable, which makes it a fantastic material for these mostly throwaway goods.

- Toys: Since HDPE is UV resistant, the toys are more able to withstand the rays’ deteriorating and discoloring impacts.

- Chemical containers: Thanks to its chemical resistance, HDPE is perfect for recycling bins, motor oil, shampoo, conditioner, and domestic cleaning supplies. When these bottles are colored or tinted, their potency is boosted.

- Pipe systems: Compared to the normal HDPE utilized in the aforementioned instances, HDPE pipe grade sheet has a greater molecular weight. It is suitable for plumbing and outdoor applications because of its strengthening and UV resistance. The temperature range for pipe grade sheet is -220 to 180 degrees Fahrenheit. It can be used in many industrial applications since it holds up well in the majority of chemical reactions.

FAQ

HDPE is recyclable from all of its forms including crates, bottles, tanks, IBCs, scrap, lumps, pipes, offcuts and sheets. At Monopoly-int we are happy to export Recycled-HDPE

Pipe Manufacturing Scrap or Redundant Stock

Our shredding capability can handle large pieces