- Need Consultation ?

Usage:

PP is used in manufacturing car batteries, bumpers, interior elements, and cladding. It also has extensive usage in the food packaging industry due to its low cost and flexibility. Nowadays, PP is used in various packaging forms and has replaced traditional materials such as paper, cellophane, and paper.

Usage:

As a hard, solid plastic, it is often used in products that require clarity, such as food packaging and laboratory ware. When combined with various colorants, additives or other plastics, polystyrene is used to make appliances, electronics, automobile parts, toys, gardening pots and equipment.

Usage:

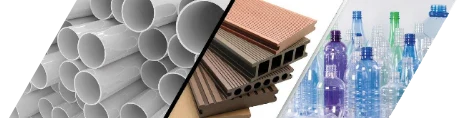

PE is the most common plastic in use today. Principal uses are in packaging film, trash and grocery bags, agricultural mulch, wire and cable insulation, toys, housewares, geomembranes and containers including bottles.

Usage: HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number “2” as its resin identification code.

Usage: used for manufacturing various containers, dispensing bottles, wash bottles, tubing, plastic parts for computer components, and various molded laboratory equipment. Its most common use is in plastic bags. Other products made from it include: Trays and general purpose containers.

Usage:

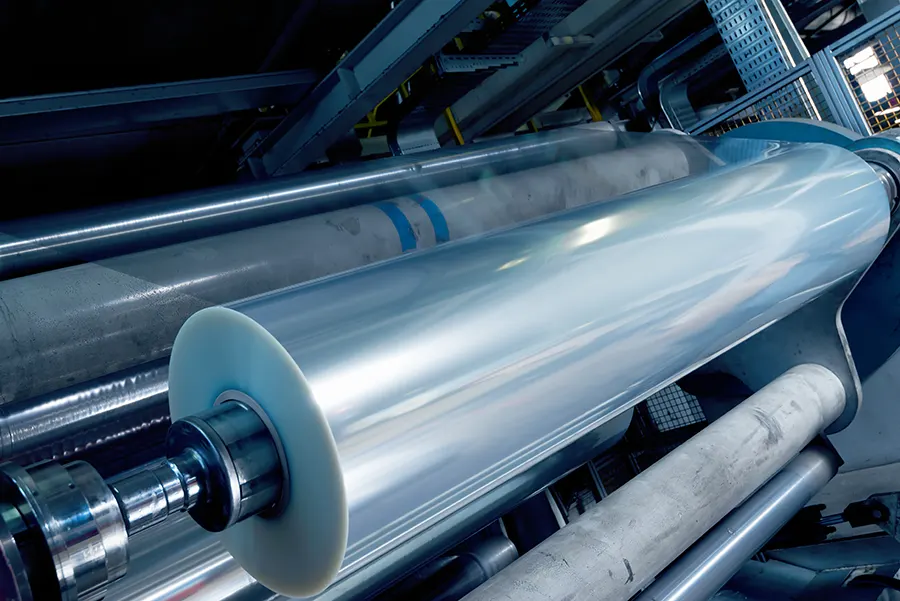

LLDPE has penetrated almost all traditional markets for polyethylene; it is used for plastic bags and sheets (where it allows using lower thickness than comparable LDPE), plastic wrap, stretch wrap, pouches, toys, covers, lids, pipes, buckets and containers, covering of cables, geomembranes, and mainly flexible tubing

Usage:

PVC is a versatile material that offers many possible applications, these include; window frames, drainage pipe, water service pipe, medical devices, blood storage bags, cable and wire insulation, resilient flooring, roofing membranes, stationary, automotive interiors and seat coverings, fashion and footwear, packaging, cling film, credit cards, vinyl records, synthetic leather and other coated fabrics.

used in gas pipes and fittings, sacks, shrink film, packaging film, carrier bags, and screw closures. MDPE plastic pipes are used for gas pipes, water and waste water plumbing designs, sewage, and drainage, steel pipe coating, wiring and cables, shrink films, and lots more.

Usage As well as its uses in computer keyboard components and LEGO bricks, ABS is commonly used to make plastic face guards for wall sockets and protective housing for power tools. It is commonly used in the automotive field too, for items such as plastic alloys and decorative interior car parts.

Usage:

As one of the most produced polymers worldwide, High Impact Polystyrene is glasslike in texture and used for all sorts of materials including yogurt containers, plastic cutlery, salad bowls, refrigerator lining, medical industry trays, and electrical insulation.

Usage:

Olefins are used as building block materials for many products, including plastics, detergents and adhesives. Ethylene is the largest volume organic chemical produced globally and a basic building block for the chemistry industry.

membranes, stationary, automotive interiors and seat coverings, fashion and footwear, packaging, cling film, credit cards, vinyl records, synthetic leather and other coated fabrics.

Usage:

Its major use is in the manufacture of tires going into treads and sidewalls, which consumes about 70% of the production. Another 25% is used as an additive to improve the toughness (impact resistance) of plastics such as polystyrene and acrylonitrile butadiene styrene (ABS).

Usage: Bentonite is used for the integral sealing of horizontal and vertical construction joints in fresh concrete, pipe penetrations and sealing concrete to steel joints. It may be used in the place of conventional PVC waterbars as an effective method of preventing passage of water at construction joints.

PP sheet is a Universal Versatile Material, excellent print surface, which can be directly fed into Printing. This PP sheets are generally used in Garment/Packing Product/Rack Tags, Packaging Boxes, Gift/Promotional Products, Vacuum Forming, Food container, Small canopy, Gate covering and many more. PP material is durable, impact resistant and weather resistant.

Optical properties

PP can be made translucent when uncolored but is not as readily made transparent as polystyrene, acrylic, or certain other plastics. It is often opaque or colored using pigments.

We can produce customize colors & sizes

PET transparent sheet can be used in various food and drug packaging materials. PET sheet itself is non-toxic and will not release harmful substances at room temperature, and its excellent ductility is the basis for packaging products. . At the same time, the surface of the PET sheet can be printed with patterns to help decorate the outside of the package or to help distinguish the items in the package.

Secondly, packaging materials for textiles and electrical components. PET sheets can effectively isolate water and oxygen, and will not allow these elements to damage the internal content.

PET sheet can be used as the basis of video tape, video tape and film.

The fourth application of PET sheet is electrical insulating materials, capacitor films, flexible printed circuit boards and membrane switches.

Advantage