Low density polyethylene (LDPE)

The Polyethylene branch of thermoplastics includes low-density polyethylene, sometimes known as LDPE. Its attributes include softness, lightness, toughness, and flexibility. The thermoplastic substance is renowned for its compatibility with low temperatures and strong resistance to corrosion. The polymer’s favorable chemical characteristics and impact resistance make it simple to manufacture or process. The melting point of it is 110 °C.

The primary distinction between LDPE and HDPE may be determined by their names alone. Since HDPE has a higher density than LDPE, the former has a greater mass-to-volume ratio.

Its structure is more branched out than in perfect rows, which accounts for its low density and volume. As a result, it is often utilized in applications where structural strength and stiffness are crucial criteria. With commercial uses in mind, Monopoly International offers LDPE.

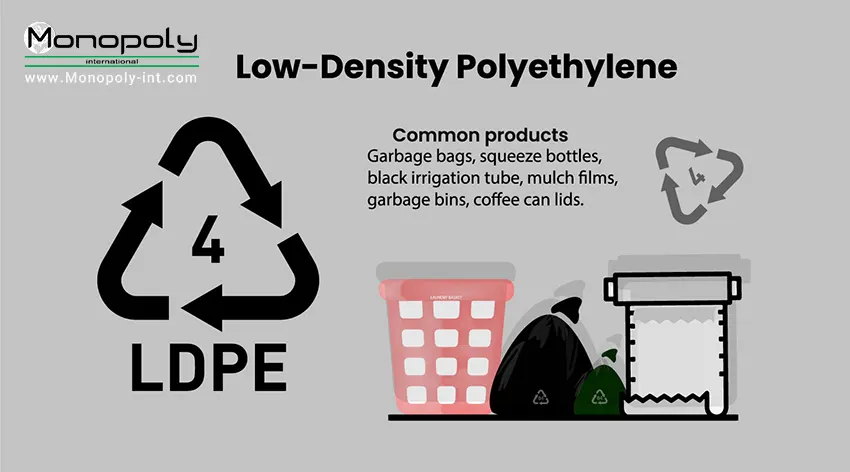

Common products that are LDPE

LDPE suppliers | How is LDPE produced?

The polyethylene monomer, like other thermoplastics, is created by the process of polymerization, in which tiny molecules known as “fractions” are eliminated and some of them are converted into the desired thermoplastic.

Currently, stirring autoclave or tubular approaches are the two most used ways to produce LDPE. However, because to their high ethylene conversion ratio, the later techniques are presently gaining prominence.

More information about other Monopoly-int services in Turkey : Recycled PET suppliers

Then, with the aid of catalytic oxide initiators and very high pressure and high temperatures (up to 350 °C), LDPE plastic is extracted from gaseous ethylene. Even before HDPE, it was the first polyethylene to have a price.

Low-density polyethylene is the polymer with shorter branches produced by the method, which results in a polymer structure with both long and short branches. Monopoly International is one of the most reliable LDPE suppliers.

LDPE characteristics

Low-Density Polyethylene (LDPE) has a broad variety of characteristics. Although there are some comparable uses for both high- and low-density polyethylene, there are a number of distinctions between them. The following are the primary qualities:

- Exceptional resistance to acids, alcohols, and weak alkalis

- incredible electrical insulating qualities

- insufficient water uptake

- high impact strength when being cold

- reasonable weatherability

- favorable processability vs cost (inexpensive)

- 910-0.940 g/cm3 for density

- little resistance to halogenated and aromatic hydrocarbons, oxidizing chemicals, and mineral oils

- Normal temperature resistance is 95°C for brief periods and 80°C consistently.

What Are Low Density Polyethylene’s (LDPE) Health Effects?

Small Density One of the safest polymers in common usage today is polyethylene, primarily because it is harmless and does not cause cancer. Polyethylene does not pose any health risks, even when consumed (in little doses). In other words, low density polyethylene is regarded as safe and non-hazardous for contact with human skin, inhalation, and ingestion.

But it should be remembered that when LDPE is made, potentially dangerous substances may come into touch with the material and mix with it while it is processed. As a consequence, during usage, chemicals may leak into food or the environment, jeopardizing the final product’s sterility. The FDA considers “virgin” low density polyethylene goods to be food-grade, hence this mostly pertains to recycled low density polyethylene.

request a quote

Low Density Polyethylene (LDPE): Is it harmful?

It is safe to use Low Density Polyethylene. As can be seen by its extensive usage in sandwich bags, bread bags, and juice bottle lamination, it is thought to be safe enough to come into touch with food.

However, it should be emphasized that recycled polyethylene does not have the same assurance of sterility and purity as “virgin” polyethylene since pollutants from the environment to which it was exposed over its lifespan may end up incorporated in the recycled product.

More information about other Monopoly-int services in Turkey : Recycled polypropylene (PP) Suppliers

Even though polyethylene is benign in certain situations, potentially dangerous foreign compounds may seep into the environment or food. Because of this, the FDA only rates “virgin” low density polyethylene polymers as being of a food-grade. It’s crucial to be aware of what and where you’re keeping your polyethylene since plastic leaching becomes worse with acidity, time spent in contact, and heat.

You can buy LDPE from Monopoly International, one of the best LPDE manufacturers in the world.

If you need a LDPE supplier, you can contact our experts Quotation submission form Contact us

How Do Low Density Polyethylene (LDPE) and High Density Polyethylene (HDPE) Differ?

High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) vary in that HDPE has a more linear arrangement of molecules along its polymer chain than LDPE, which gives it better stiffness, strength, crystallinity, and lower permeability.

As a result of less frequent branching within the polymer chain, which enables HDPE molecules to organize themselves closer together, there is a decrease in crystallinity. Another benefit of having tightly packed molecules is lower permeability, which gives HDPE stronger chemical resistance. Additionally, HDPE gains from enhanced heat resistance, which enables it to function up to 100oC. These characteristics make HDPE an excellent choice for certain heavier-duty applications that call for greater chemical resistance and rigidity.

Applications for HDPE and LDPE differ due to their vastly varied thermo-chemical-mechanical characteristics. The working circumstances of the product must be taken into account when choosing the best plastic for a certain application in order to ensure that the chemical-mechanical requirements are met. See our companion page on HDPE for additional details on the qualities and uses of high density polyethylene. Custom plastic cutting boards of various sizes and forms are available from Monopoly International suppliers.

The Prospects for LDPE Plastic

The worldwide LDPE market had a capacity of 22 million tons in 2020, and Mordor Intelligence’s research indicates that it will grow at a CAGR of 3% from 2021 to 2026.

The major LDPE users, the instruction and packaging sectors, will have a substantial decline in sales as a result of the Covid-19 outbreak, which will undoubtedly have an impact on the figures. However, there is some good news: despite the epidemic, the e-commerce and healthcare industries have performed well.

With over 30% of the global market, Asia-Pacific was the area with the highest production and consumption of LDPE plastic. Construction and packaging industries are expanding quickly in nations like China, Japan, and India (Even being in the midst of a pandemic).

The tremendous devastation brought on by the pandemic may be short-lived since scientists have developed a Covid-19 vaccination and people have begun to come out, go to work, and attempt to restore normalcy.

The LDPE market momentum will remain steady until the conclusion of the projection period thanks to the quick economic recovery in the Asia-Pacific region and expansion in the packaging and construction verticals.

LDPE Applications

Even LDPE plastics are quite handy since they are so lightweight. Pricing wash bottles, shopping bags, containers, dispensing bottles, tubings, computer components, etc. are the principal uses for it. Here are a few of the most significant applications:

- Applications for Packaging: Due to the low cost and good flexibility of LDPE material, it is widely used in plastic packaging for both consumer and industrial sectors. Examples include lunch boxes, squeeze bottles, pharmaceutical packaging, liners, trash bags, liners, laminations, and food packaging films.

- Consumer Products: Flexible and lightweight toys, household goods, and agricultural films are all examples of consumer goods.

- Pipes & Fittings: LDPE is the preferred thermoplastic for water-related applications because to its low water absorption and lightweight characteristics. Water pipelines, hoses, etc. are an example.

- Low-density polyethylen is an excellent material for cables and wires because it has good electrical characteristics.

FAQ

LDPE lends itself to a wide variety of applications, many are integral to our everyday lives. One of the most common uses is plastic shopping bags.

Its flexibility, toughness and low weight are key driving factors for its sustained demand since its inception.

While LDPE standards for low-density polyethylene, HDPE standards for high-density polyethylene.

HDPE has a crystalline molecular structure, giving it a higher density, while LDPE has an irregular branched structure leading to its low density.

HDPE has a higher tensile strength, higher chemical resistant properties and is able to withstand higher temperatures than LDPE. A semi-rigid, touch material, it is far less flexible.